What We Offer

We offer a range of custom design and fabrication services, including furniture repair and restoration, custom furniture design and fabrication, public art and sculpture commissions, architectural fabrication, and contract CNC machining. Whether you’re a private client, contractor, or institution, we bring precision, technical expertise, and thoughtful design to every project.

Led by Ben Ezzell, an Enid, Oklahoma based artist, attorney, and fabricator, we serve clients throughout the region.

-

Professional furniture repair and restoration services are available for residential and commercial clients throughout Enid and the surrounding region. From structural stabilization and joinery repair to veneer work, refinishing, and hardware replacement, each piece is handled with care.

Whether restoring a family heirloom, repairing a damaged dining table, or revitalizing a built-in element, the focus remains on longevity, structural integrity, and respect for the original design. Modern and antique pieces are both welcome.

-

Original, made-to-order furniture is designed and fabricated for homes, businesses, or institutions. Projects range from dining tables and custom storage to retail fixtures and interactive marketing displays.

Each commission begins with a collaborative design process, including concept development and 3D modeling when appropriate. Fabrication takes place in the Enid workshop using hardwoods, sheet goods, steel, brass, plastic, concrete, and mixed materials. Large-format CNC capabilities allow for precision joinery, complex geometry, and repeatable accuracy.

From one-of-a-kind statement pieces to functional built-ins, every project is unique!

-

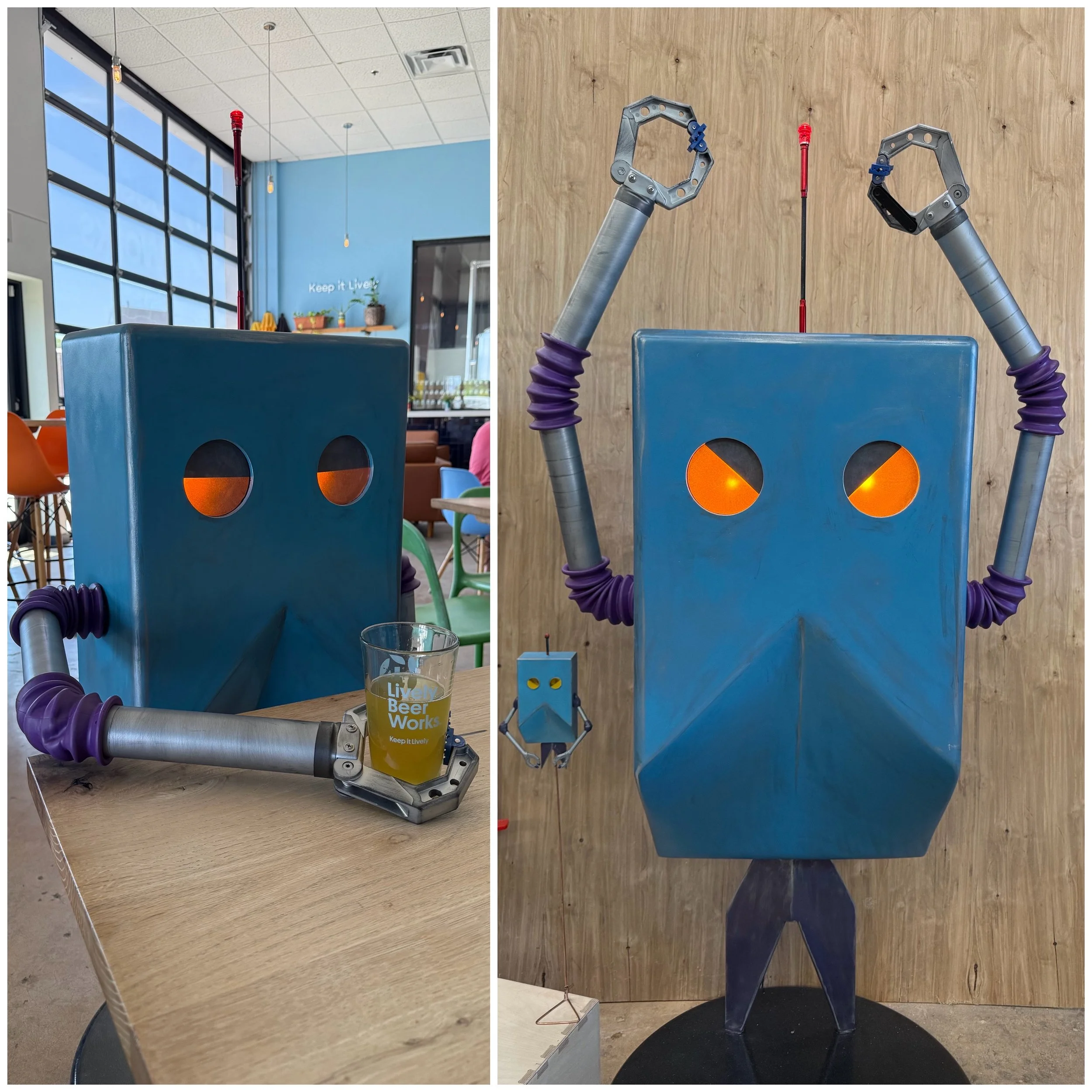

Commissions are accepted for sculptural work, kinetic installations, and site-specific public art. Projects include private commissions, corporate installations, outdoor structures, and immersive environments. Our emphasis is always on interactivity and real-world engagement.

Experience with large-scale fabrication and complex assemblies supports projects from concept development through fabrication and installation. Services include proposal collaboration, design refinement, material selection, structural planning, and coordination with architects, contractors, and municipalities.

Based in Enid, Oklahoma, projects are undertaken regionally and nationally.

-

Design-assist fabrication and precision contract CNC machining are available for contractors, designers, artists, and manufacturers. Services include custom architectural components, decorative panels, scenic environments, retail fixtures, and short-run production work.

The 5’ x 8’ CNC platform supports large-format cutting of plywood, hardwood, MDF, HDPE, and other sheet goods. Client-provided files (DXF, SVG, VCarve, and other common formats) are accepted, and design development support is available when needed.

Beyond CNC machining, fabrication capabilities include custom vacuum-formed panels, silk screening, cast and sculpted concrete elements, 3D foam carving, and mixed-material assemblies. Projects often combine digital fabrication with hands-on processes to achieve distinctive, out-of-the-box results that standard production methods cannot replicate.

For larger or technically complex installations, a trusted network of collaborators with specialized skills can be engaged to scale capacity while maintaining design integrity and project continuity.

From fully developed architectural elements to cut-from-your-file production parts, work is executed with precision, creative flexibility, and dependable turnaround times.

Our Process

Concept Development

Every project begins with a conversation. Goals, constraints, site conditions, budget, and timeline are clarified to define the scope of work. Early sketches, reference imagery, and feasibility discussions help shape a clear direction before moving into detailed design.

Design & Material Selection

Concepts are refined through drawings, digital modeling, and mockups. Structural requirements, durability, aesthetics, and fabrication methods are considered in tandem to ensure the design can be executed with precision. Materials are selected for performance, longevity, and visual impact.

Fabrication

Fabrication takes place in the workshop using a combination of digital tools and hands-on techniques. Large-format CNC machining, custom forming, sculptural processes, and mixed-material assembly are integrated as needed. Attention to detail and build quality remain central throughout production.

Installation

Completed work is delivered or installed with care and coordination. For architectural and public projects, installation may involve collaboration with contractors, engineers, or site managers to ensure safe and seamless integration. The final result reflects both design intent and real-world performance.